Department: Cranioplasty surgery

Patient: male, age: 37Y

Dr. Idan Levitan

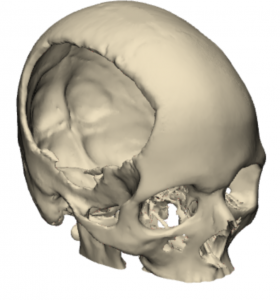

Services: Segmentation, surgery planning, anatomy model, PSI

This is a fascinating neurosurgery case that we took to the next step using our cutting-edge 3D technology.

It usually comprises of a two-part surgery. A craniectomy and a cranioplasty.

As the human brain is protected by the skull, it is also a an incompressible ‘closed box’. In traumatic brain injury or stroke aside from the event itself, and secondary brain damage can be caused by the increased pressure inside the ‘closed box’ (skull), whether from the bleeding in traumatic brain injury or from the edema and swelling of the brain. A decompressive craniectomy surgery can prevent the secondary neurological damages.

In this case, Dr. Idan Levitan from Neurosurgery Department in Beilenson hospital asked us to create a customized implant.

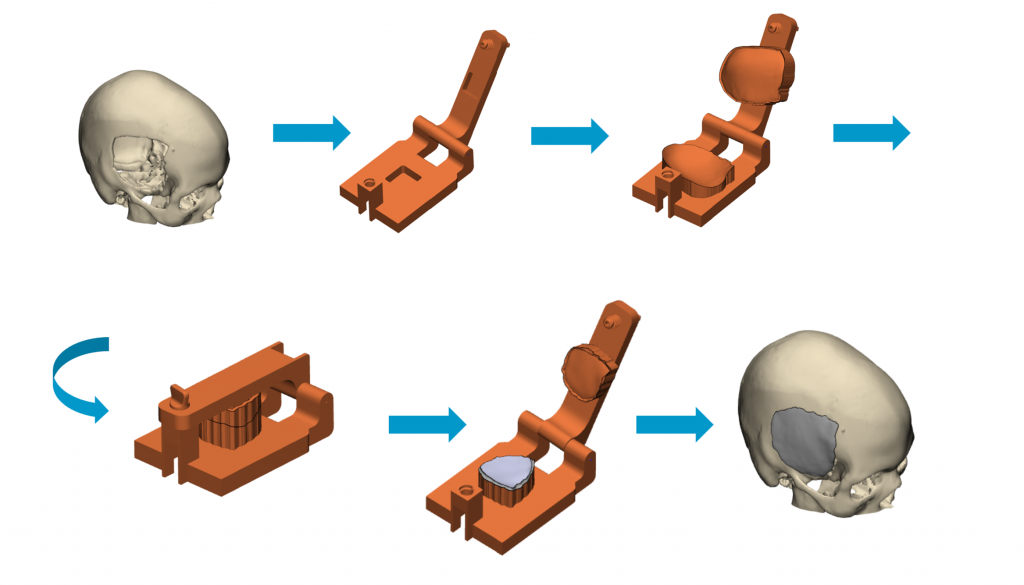

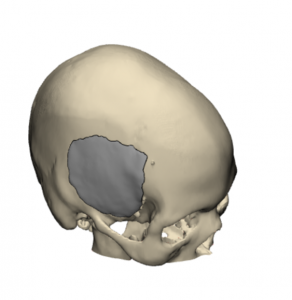

At Synergy3DMed, we used the CT taken after the craniectomy to supply the patient with a perfectly fitting piece for the skull.

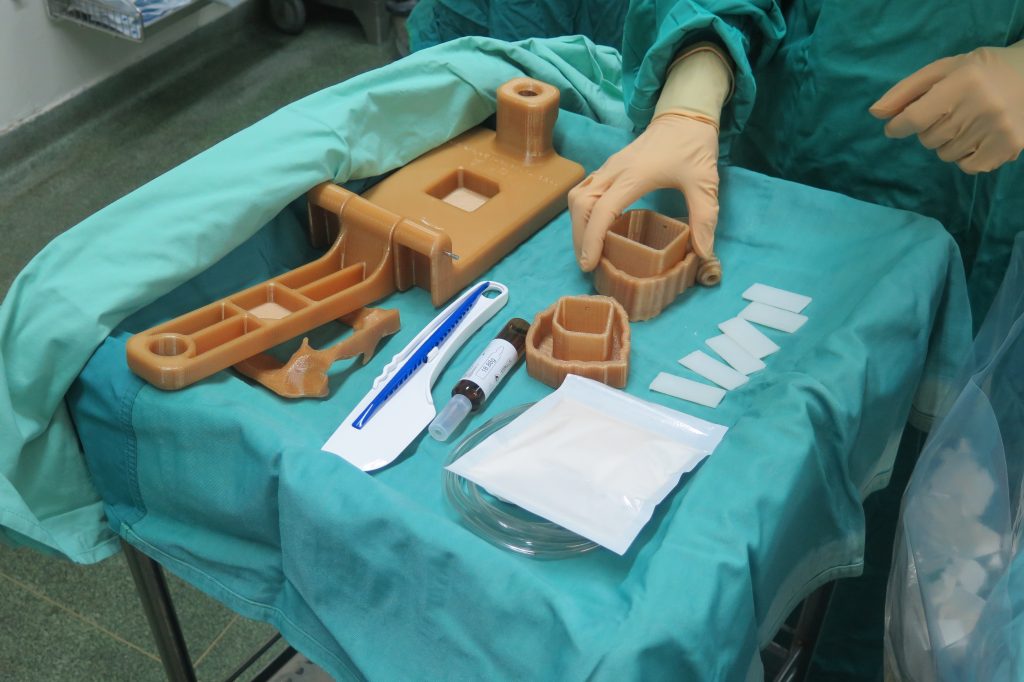

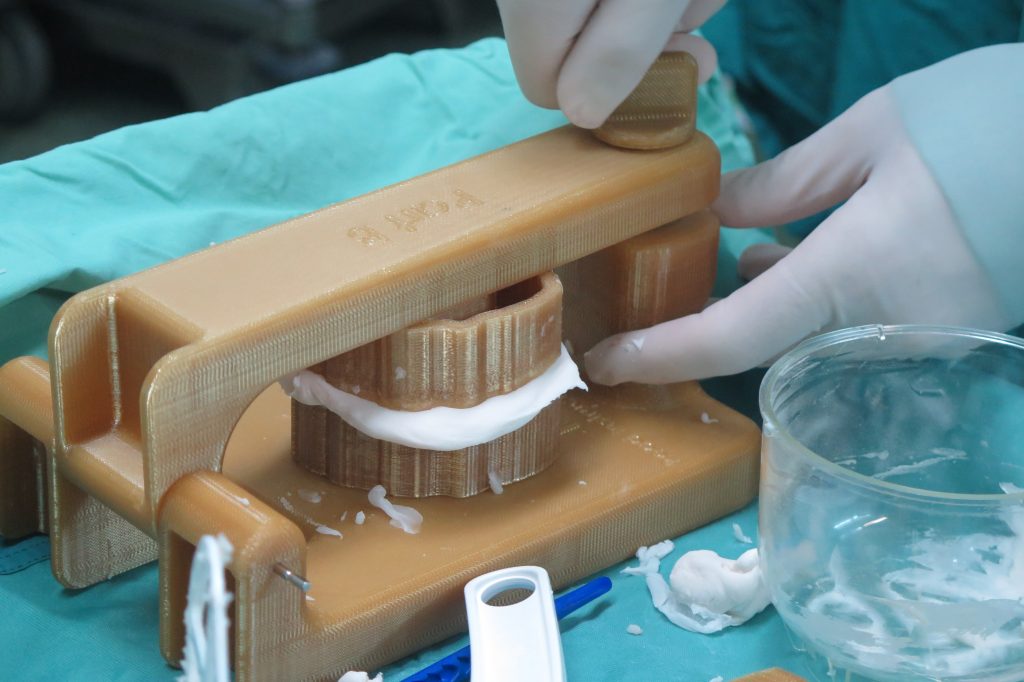

Once the physicians approve the implant’s shape, we 3D print a patient-specific kit consisting of molds and clamp both of which are sterilized prior to surgery. During the surgery, the surgeon pours a precise, predetermined amount of cement powder from Johnson & Johnson into the 3D printed customized mold. This cement bone piece can be tested on a sterile 3D printed anatomical model, prior to using it on the patient. The sterilization serves to reduce the risk of secondary infection.

Using our technology, surgeons can reduce surgery time. It also resulted in a perfectly fitting and symmetrical implant for the patient.

Each day, we strive to improve medical processes, making them faster and more precise, to improve clinical outcomes and patients’ life quality.